Most immersion cooling containers conduct heat through the two liquids to take away the heat of the running miners, so that the heat will not be too high even in high-speed operation. I believe everyone knows this principle, but do you know how it works and what its parts do? Let me explain it to you next!

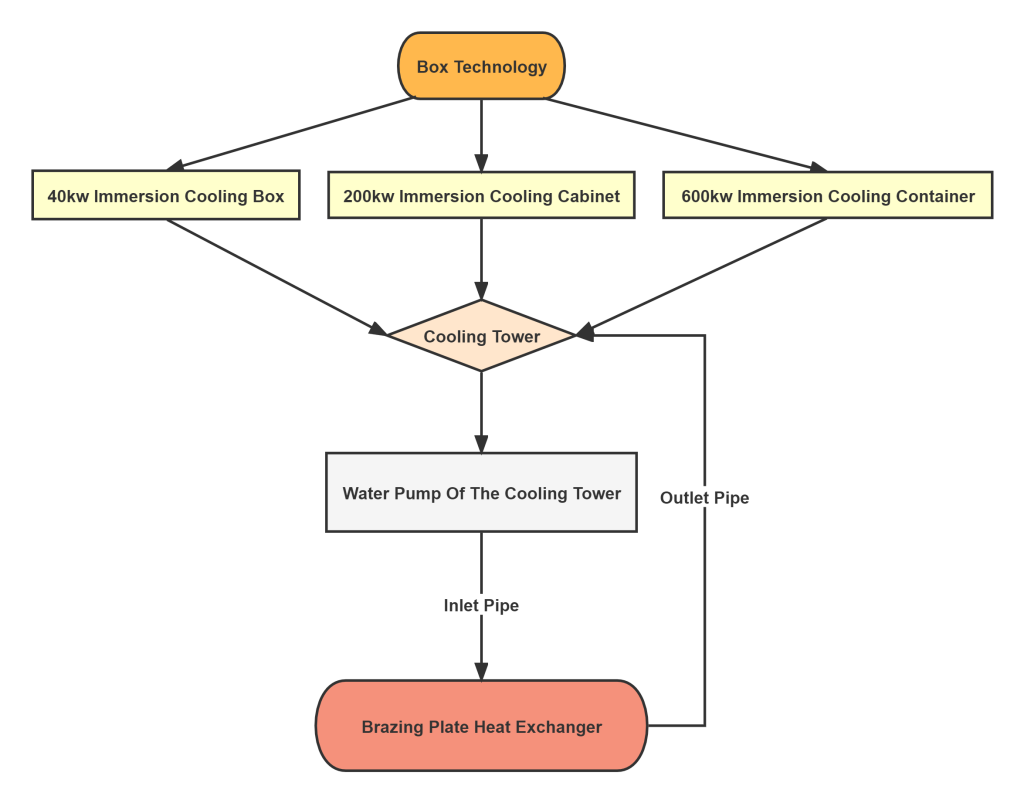

Box Technology immersion cooling container

The two liquids in the Box Technology immersion cooling container are water and oil and they have different objects to work on. The water is mainly to let the oil cooling while the oil cools the miners. The heat of the miner can be taken away by the principle of cold water in and hot water out. That is the cold water enters the plate heat exchanger of the immersion cooling container, and exchanges heat with the hot oil inside then turns into hot water. The hot water returns to the cooling tower for cooling into cold water, while the hot oil inside the machine turns to low-temperature oil after the heat is taken away by the circulation of cold water, and then flows back to the liquid cooling tank. The water and oil circulate continuously to cool the miner.

▼Principle of water cooling of the immersion cooling container

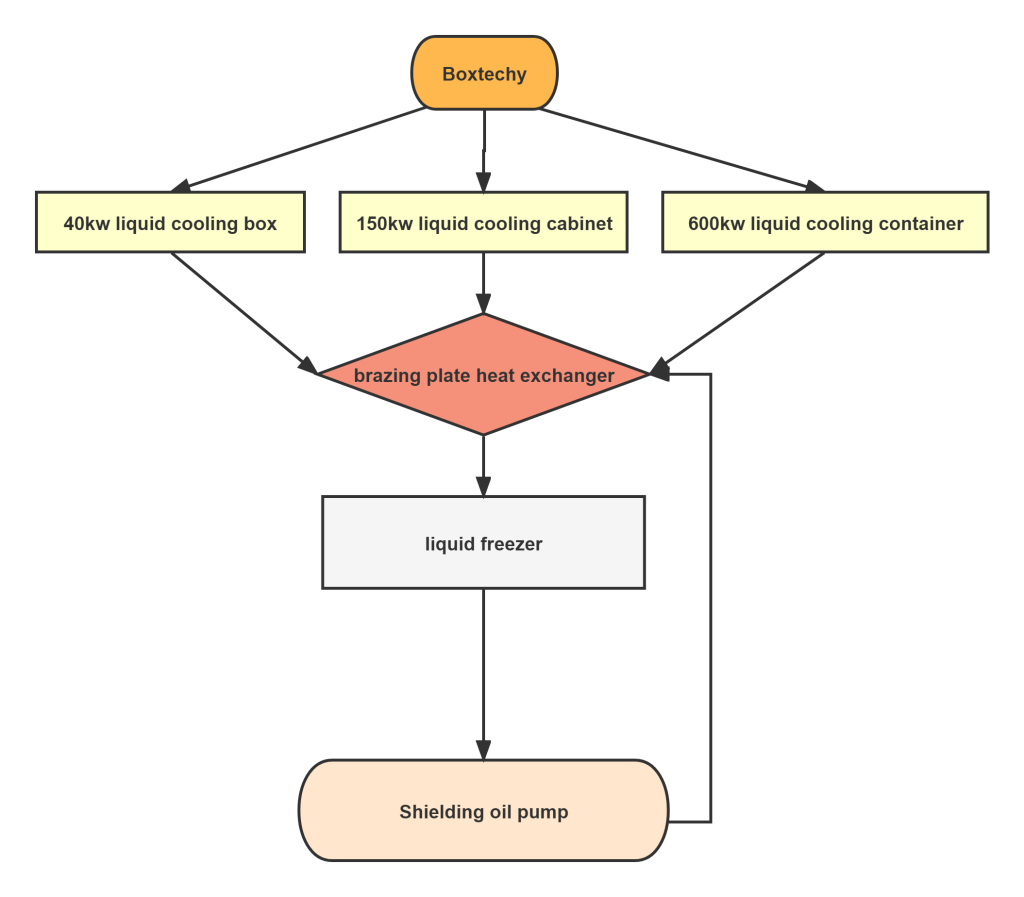

▼Principle of oil cooling of the immersion cooling container

immersion cooling container – Oil

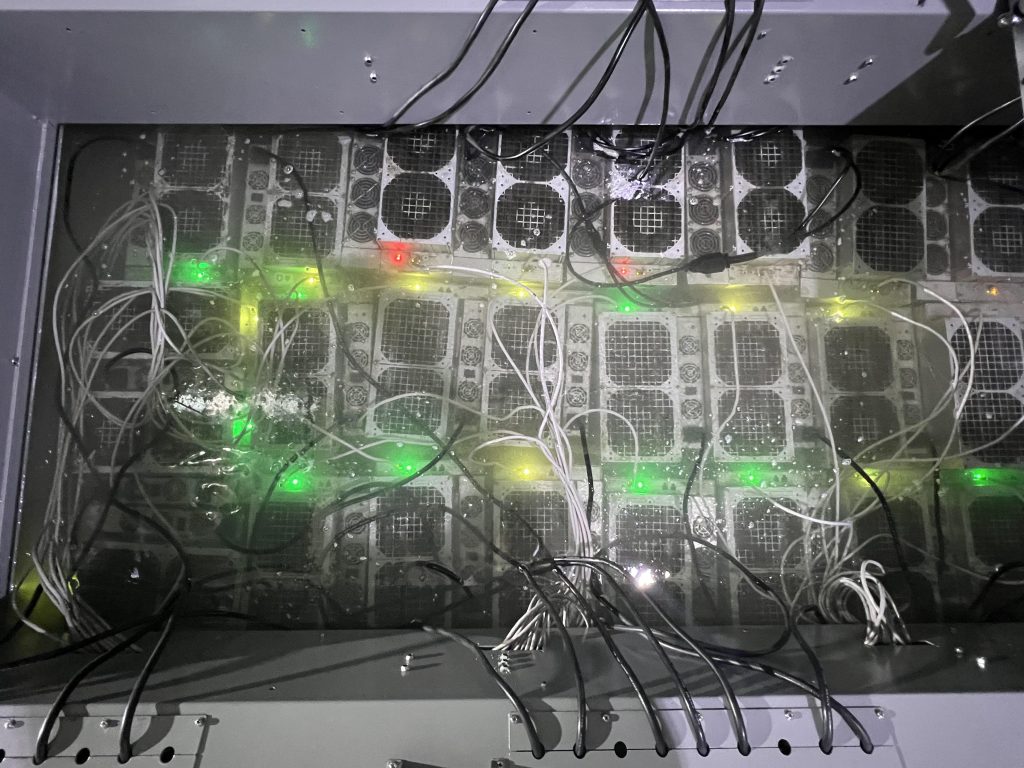

When using the Box Technology immersion cooling container, we can see that the oil is obviously cloudy, but this is a normal phenomenon, which indicates that the oil temperature is lower at this time, which can make the miners cool better. When the oil is clear enough to see the bottom, it means that the temperature of oil is very high, about 50-60 degrees. This is actually a bad situation, but there is nothing to worry about, because the protection device of immersion cooling contains will power off the machine when the oil reaches the specified temperature. So even if the customer goes out, there is no need to worry about the over-loading of the machine.

▼Oil being used

immersion cooling container – Plate Heat Exchanger

Box Technology immersion cooling container adopts brazed plate heat exchanger. Compared with traditional brazed plate heat exchanger, it has high heat transfer efficiency, compact structure and small footprint, which can save costs for customers to maximize profits. The heat exchanging area consists of a thin corrugated metal plate, which is stamped into corrugated shape. The cooling medium and the heating medium flow through the two channels separated by the plates respectively for heat exchange. The designated heating medium is changed into a low-temperature medium and then re-enters the immersion cooling containers, so that the mines inside can gradually cools down to the most ideal state. Among many liquid cooling equipment, the plate exchanger plays a decisive role. The larger the plate exchanger in an equipment, the more heat it can bring out, and the performance of this equipment is relatively good.

▼Plate Heat Exchanger

immersion cooling container – water

Under normal circumstances, only tap water with a PH of corresponding value can be used in the immersion cooling container. Only in this way, the equipment will not be damaged. If the customer is in the cold north, antifreeze is also required to prevent serious damage to the machine due to accidental water pipe burst. Box Technology recommends that when using immersion cooling container, the water used in the water tower should not be groundwater or other water sources with more impurities as much as possible, because this will cause irreparable damage to the plate exchanger and even direct damage may cause the machine to scrap.

▼water

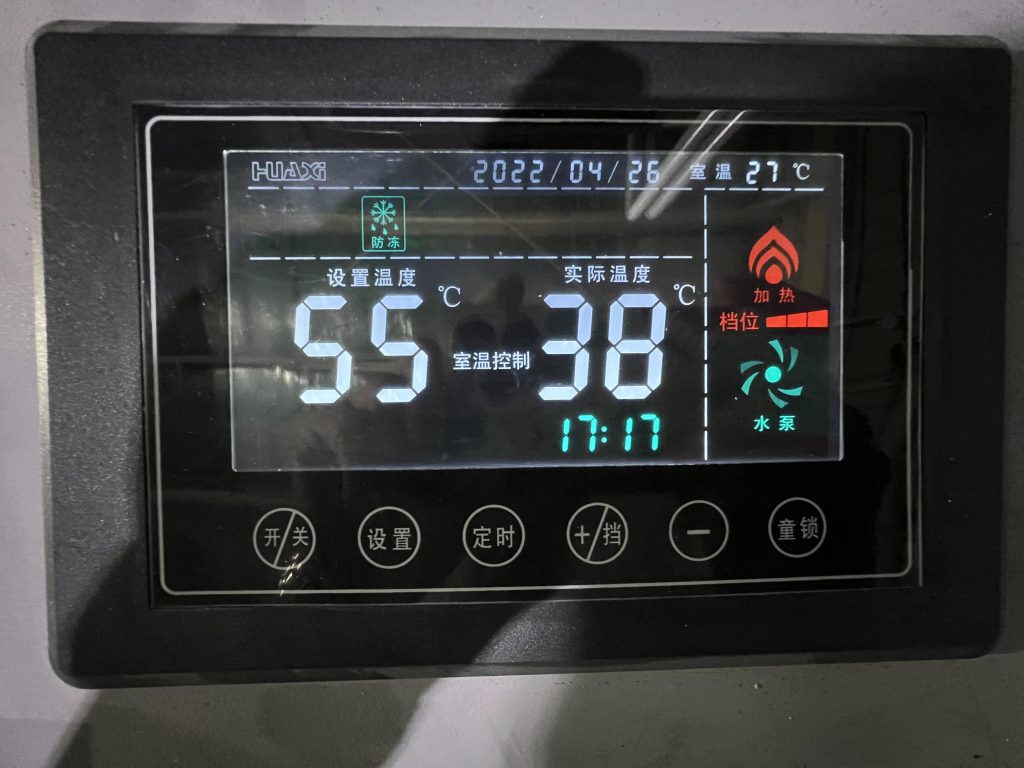

immersion cooling container – Electric control system

Box Technology immersion cooling container’s electrical control system consists of mainboard, cellphone APP and liquid crystal display (LCD). This is the nerve center that controls the immersion cooling produce. Customers can view various data information on the control panel, and can also download the APP to learn the status of the immersion cooling produce of real-time. Compared with the ordinary electrical control system, Box Technology ‘s electrical control system is more cost-effective. Not only can it monitor and control liquid level and temperature on a real-time, but also has super-high temperature alarm and leakage protection devices, which can effectively prevent accidents.

▼LCD

There are not only the above parts in the immersion cooling container, but also new important parts for different products. I will not introduce them one by one. If there is any doubt about immersion cooling container, feel free to contact Box Technology , I believe Box Technology can solve it!