Immersion cooling is a typical direct contact liquid cooling. It immerses the heating electronic components in the cooling liquid and relies on the liquid flow to circulate the heat away. It is mainly divided into single-phase and two-phase immersion cooling technology. Our Box Technology uses simple and easy-to-operate single-phase immersion cooling technology. Today let’s get into the vital part of single-phase immersion cooling technology: the Plate Heat Exchanger.

The laws of physics explain that the energy of a system continues to flow until it is in equilibrium. According to the laws of thermodynamics, heat flows from one system to the other due to the difference in heat or temperature between the two systems.

A heat exchanger works according to the equilibrium principle. Heat exchangers play the most vital role in heat transfer from one liquid to another. There are different types of heat exchangers and one of them is the plate heat exchanger (PHE). The plate heat exchanger extracts heat from the surface and separates the cold fluid from the hot fluid.

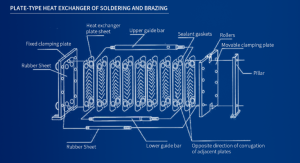

Plate-type heat exchanger

In the 1920s, Dr. Richard Seligman invented the PHE (plate heat exchanger). A plate heat exchanger uses a series of metal plates to transfer heat from one type of fluid to another. These plates are positioned on top of each other to form a series of channels so that the fluid can move between them.

Compared to conventional heat exchangers, the main advantage of a plate heat exchanger is that the fluid is distributed over the plates because the fluid is exposed to a larger surface area. This increases the heat transfer rate and greatly accelerates the rate of temperature change.

Today, plate heat exchangers are used extensively with very small welded designs in the hot water section utilizing millions of combination boilers. With such a small size, the high heat transfer efficiency increases the flow of DHW (domestic hot water) in the combination boiler.

Small plate heat exchangers have a significant impact on home heating and hot water. Large commercial models utilize gaskets between the plates, while smaller models tend to be welded.

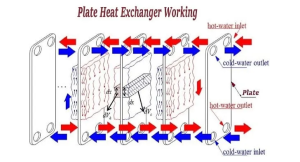

Plate Heat Exchanger Working

A plate heat exchanger is a heat exchanger that contains a series of metal plates that transfer heat between fluids. Plate heat exchangers work on the principle of thermodynamics. In these exchangers, each plate has a closed hollow tubular shell.

The plates are arranged in such a way that the heat is exchanged through half of the plates forming elongated rectangular channels. The operating fluid moves between these twisted, narrow channels.

The plates of this exchanger are surrounded by gaskets to control the flow of fluid. The washers can be rotated to block the right or left side of the hole. These gaskets are arranged so that only one fluid (i.e. the oil being heated) is distributed on one plate and the other fluid (i.e. hot water) is distributed on the next plate.

What happens is that the channels between the plates are of different temperatures and the hot ones always flow to the cold ones. Therefore, the hot fluid transfers some of its thermal energy to the cold fluid. These two fluids never meet or mix, they are always separated by the metal plate walls. The heat is only transferred through this. Thus, the hot fluid will be cooled and the cold fluid will be heated.

With this arrangement, the cold liquid and the hot liquid alternately pass through the plates, and heat exchange occurs as a result. The plates have a large surface area; therefore, they have a high heat transfer rate compared to a tubular heat exchanger.

As you can see in the diagram above, the coolant inlet (blue) is at the bottom and the coolant outlet is at the top, while the opposite is true for the hot fluid outlet (red). The coolant flows upward and the cooled liquid flows downward, transporting heat through the plates. After completing this process, the heating medium is eventually cooled, while the cooling medium is heated.

The heat transfer principle and design of the plate heat exchanger are characterized by compact design, low heat loss, a wide range of applications, flexible operation, high heat transfer efficiency, small installation area, and easy installation and cleaning functions.

The above describes what plate heat exchangers are and how they work. For more information on this, you can contact our email at info@boxtechy.com.